Introduction

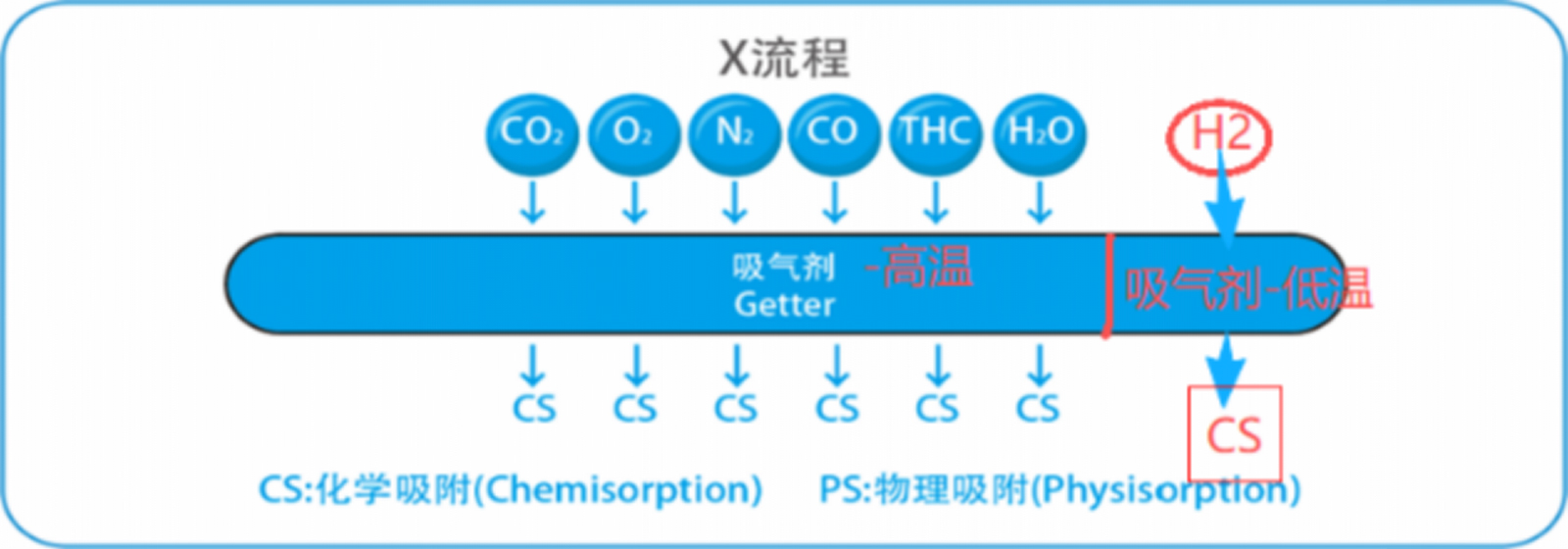

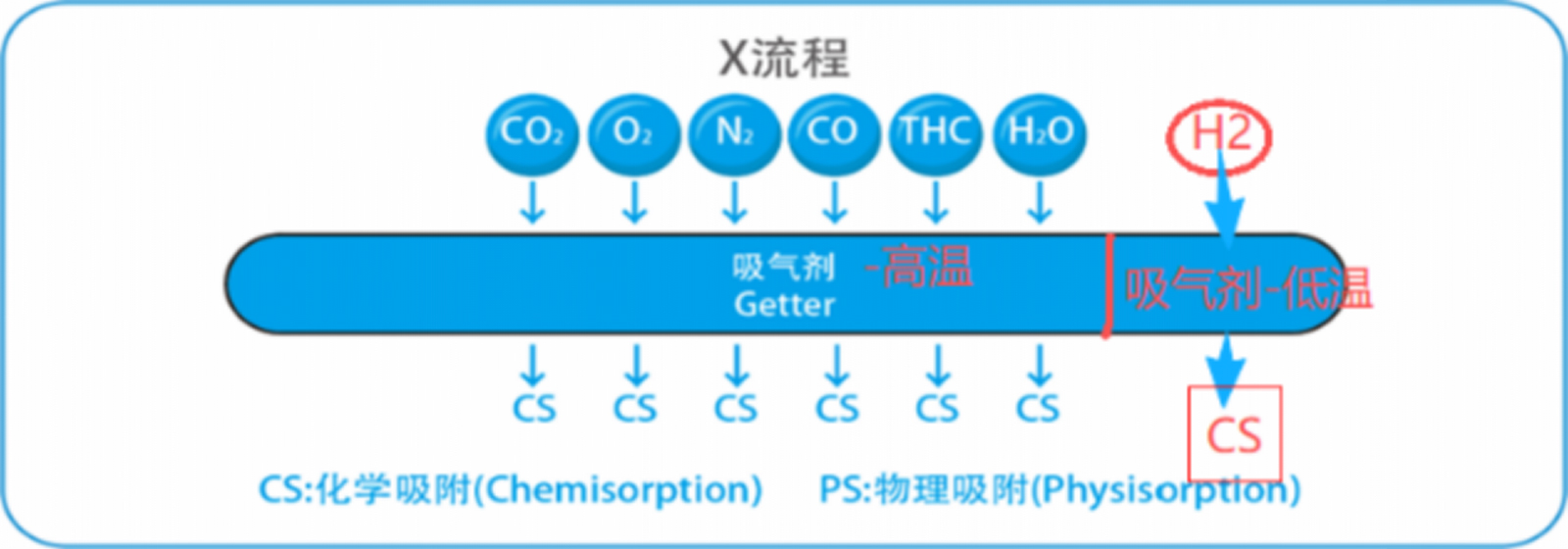

This purifier employs the XX process to purify neon, xenon, and krypton gases. The feed gases—argon-neon mixture, xenon, and krypton—enter the purifier and pass through a high-temperature getter reactor, where impurities such as H

2O,O

2,CO,CO

2,CH

4,N

2, and NMHC are removed to levels below 1 ppb. The gas stream then flows through a cooling system to return to ambient temperature before entering a low-temperature getter reactor, where H

2 impurities are removed.

XX Process

Process Flow

Process Flow

High-temperature getter removes CO

2、O

2、N

2、CO、THC、H

2O

Low-temperature getter removes H

2

Once the getter reactors are saturated, they cannot be regenerated and must be replaced as a whole

Application Areas

Semiconductor & Electronic Materials

High-Purity Gas Analysis

Product Features

1.Ultra-High Purification Accuracy

★ Proprietary catalyst technology with synergistic chemical adsorption, achieving impurity removal to depths of ≤1 ppb.

2.High-Stability Design

★ It utilizes internationally renowned brand components; full-automatic orbital welding by Swagelok, integrated with advanced explosion-proof strategies to ensure safe and stable system operation.

3.Strong Anti-Fluctuation Performance

★ Designed with 120% redundancy per protocol, ensuring stable gaseous index output under fluctuating working conditions.

4.High Accident Resilience

The purification unit features power-off protection functionality.

5.Smart IoT Operation & Maintenance

★ Fully automated operation with remote monitoring

★ Fault early warning and interlocking + operational data traceability system

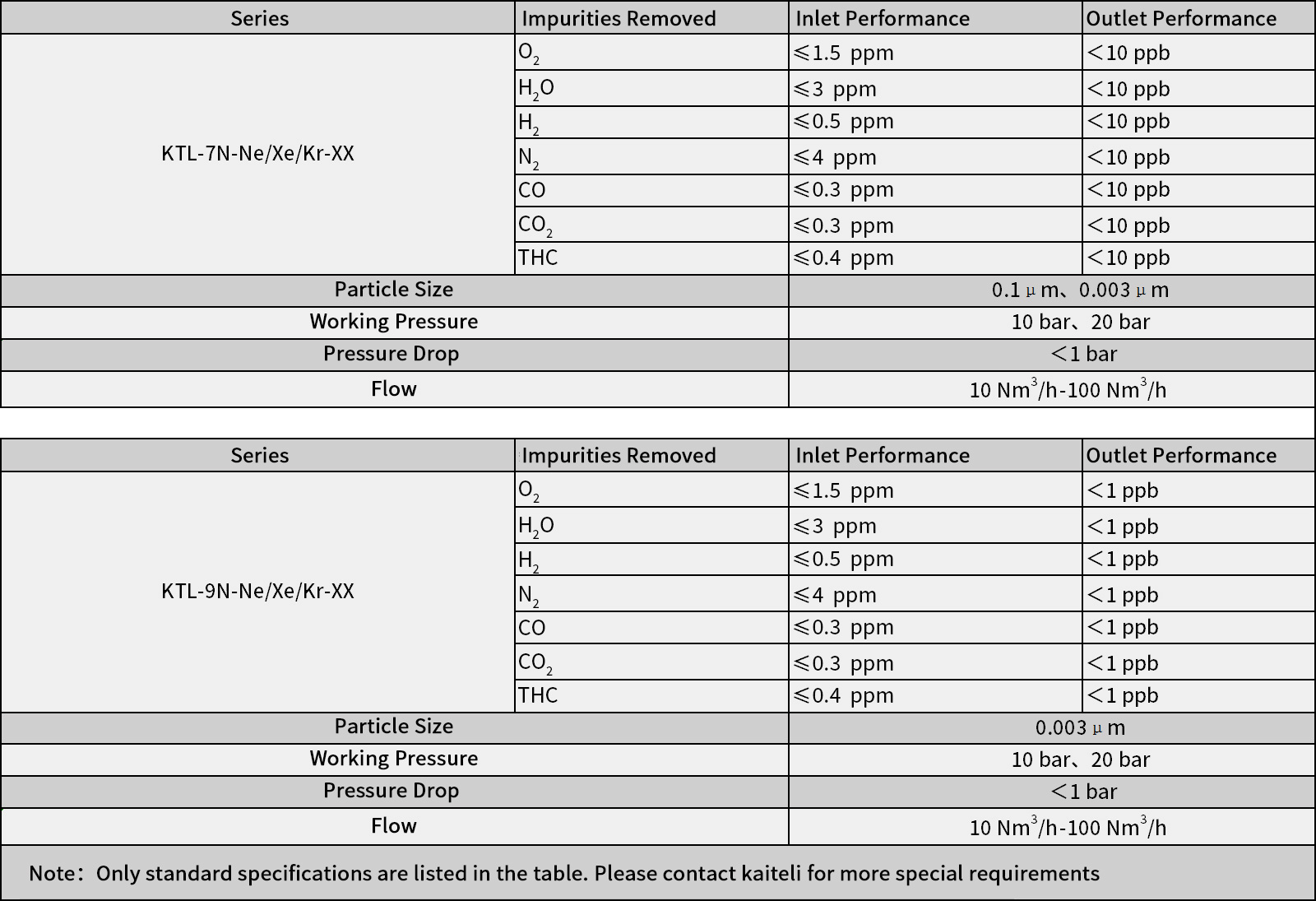

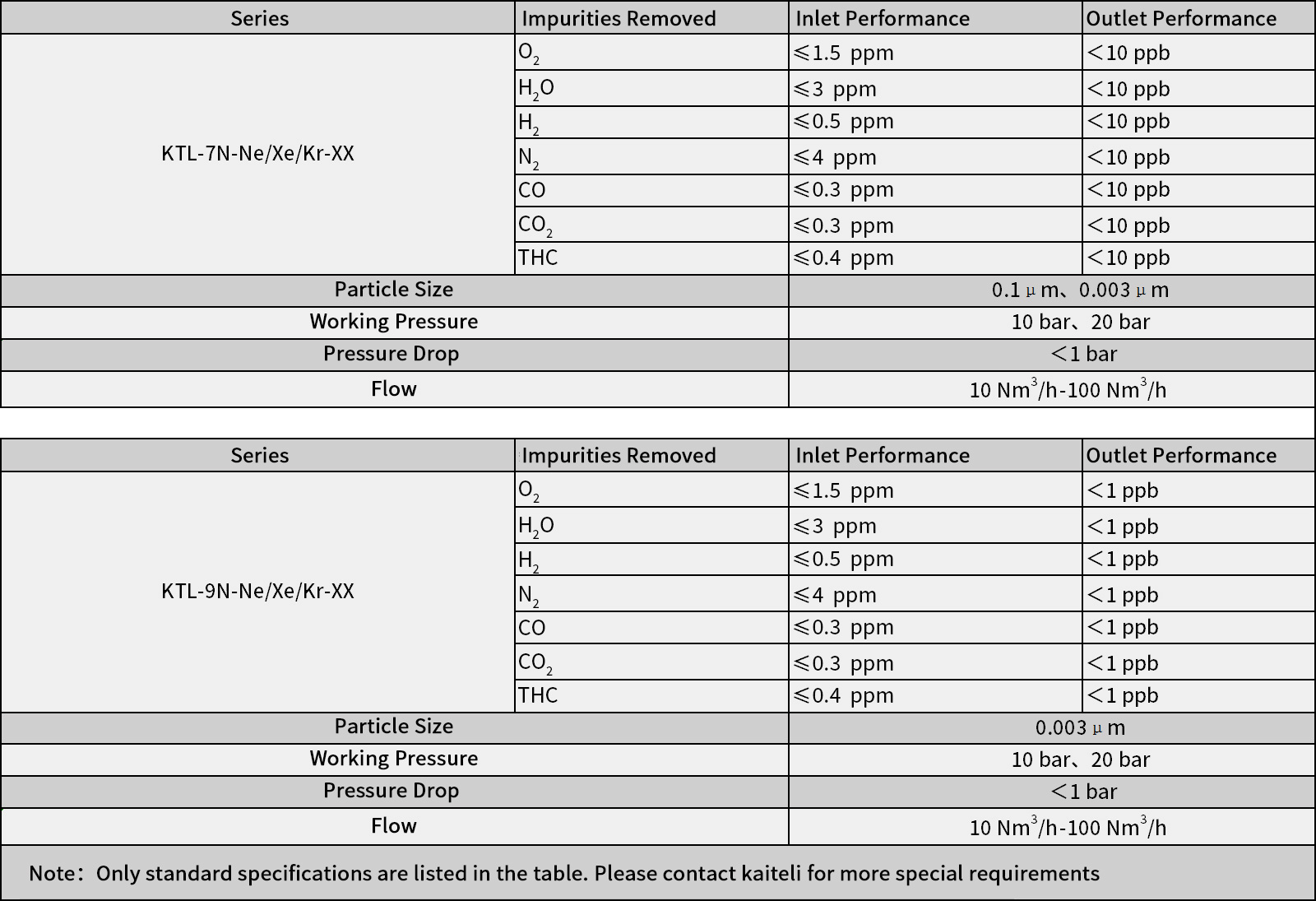

Technical Parameters