Introduction

This purifier adopts the WX process for hydrogen purification. The feed hydrogen enters the purifier, where ambient-temperature adsorption initially removes H₂O, O₂, CO₂, and CO to below 10 ppb. Once the adsorbent bed reaches saturation, it undergoes regeneration. The ambient-temperature adsorption reactors are designed with one unit in operation and one on standby, enabling continuous operation. Subsequently, a high-temperature adsorption process further removes impurities such as H₂O, O₂, CO, CO₂, CH₄, and N₂ from the hydrogen to below 1 ppb.

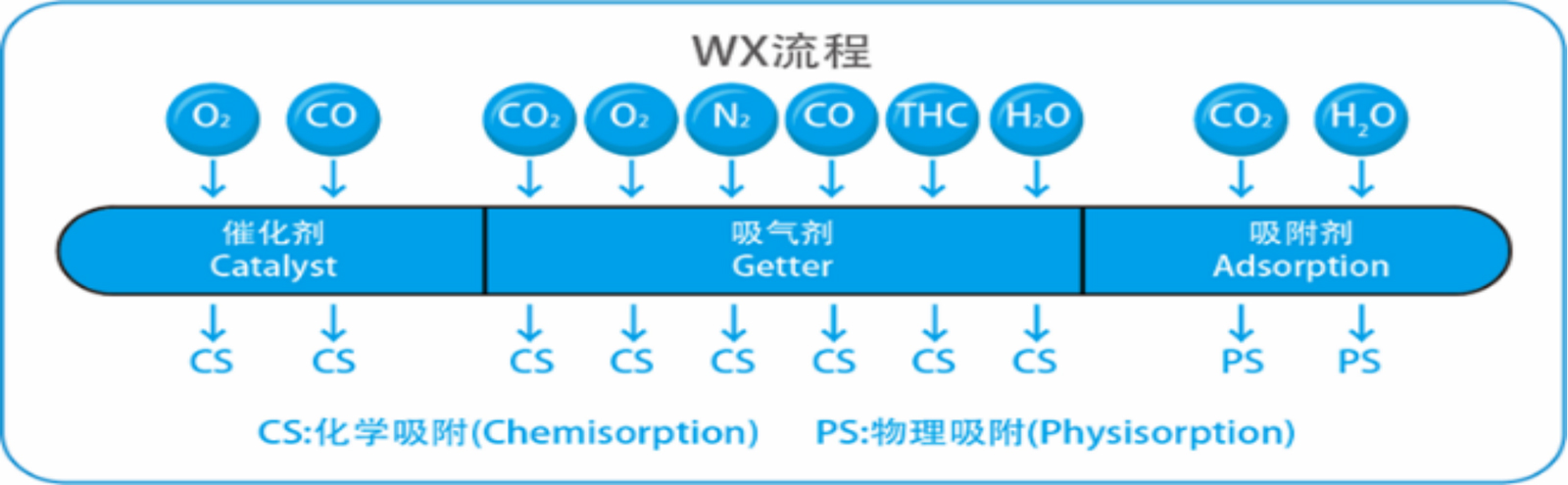

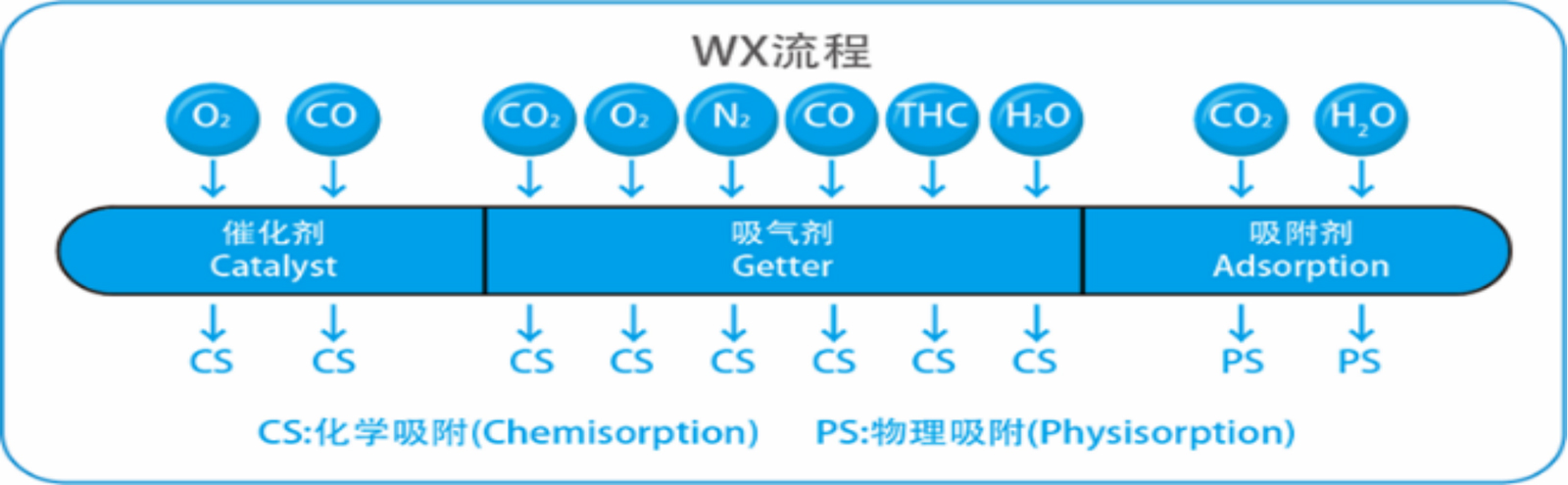

WX process

Process Flowa

Process Flowa

Gas absorption removes CO₂, O₂, N₂, CO, THC, and H₂O.

Adsorbent removes O₂, CO₂, and H₂O.

After the adsorption reactor reaches saturation, it is regenerated by heating with hydrogen. Dual towers switch over to ensure continuous gas supply.

The gas absorption reactor cannot be regenerated after saturation and requires full replacement.

Application Areas

Semiconductor, LED, Laser, and Solar PV Industries

Optical Fiber Industry

Integrated Circuit Manufacturing Industry

High-Purity Gas Analysis

Product Features

1.Ultra-High Purification Accuracy

★ Proprietary catalyst technology with synergistic chemical adsorption, achieving impurity removal to depths of ≤1 ppb.

2.Long-Life Design

★ It utilizes internationally renowned brand components; full-automatic orbital welding by Swagelok, integrated with advanced explosion-proof strategies to ensure safe and stable system operation.

★ Catalyst service life: ≥ 3 years | Unit operational lifespan: ≥ 15 years

3.Strong Anti-Fluctuation Performance

★ Designed with 120% redundancy per protocol, ensuring stable gaseous index output under fluctuating working conditions.

4.High Accident Resilience

The purification unit features power-off protection functionality.

5.Smart IoT Operation & Maintenance

★ Fully automated operation with remote monitoring

★ Fault early warning and interlocking + operational data traceability system

Technical Parameters